Biomass combustion particles are a new type of fuel, and biomass pre-treatment systems are used to treat wood materials such as straw, wood boards, and branches

Biomass combustion particles are a new type of fuel, and the biomass pre-treatment system is used to treat wood materials such as straw, wooden boards, and branches. The entire line realizes fully automated operations from soil removal, iron removal to crushing. The particle size of crushed straw is 80-200mm, with a production capacity of 10-50t/h, meeting the discharge requirement of soil impurity content less than 5%; Breaking the problem of low yield and poor adaptability to materials in traditional straw screening and crushing pretreatment. The generated biomass fuel can be prepared into RDF for use in biomass power plants, central heating boilers, and drying projects.

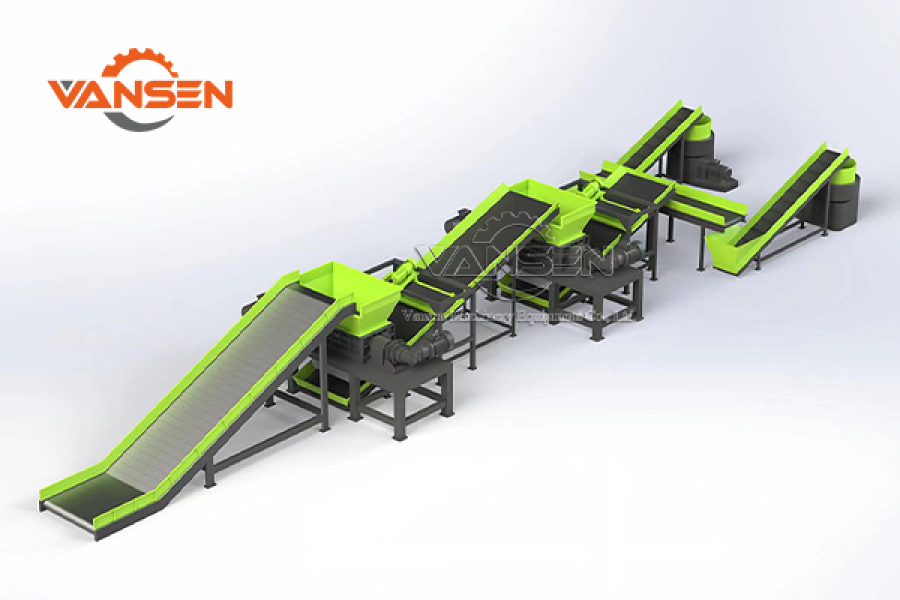

Materials such as straw, wooden boards, and branches are uniformly fed into the shredder by feeding equipment such as forklifts. The shredder works by cutting, tearing, and squeezing to crush and dispose of the materials. The crushed materials are transported to the finished material area or transferred to the next disposal process through a belt conveyor. The metal materials can be selected through a magnetic separation device and then crushed into a fine crusher. The size of the finely crushed product can reach 10-50mm, To meet the feeding size of the granulator, the RDF briquetting machine is pressurized, densified, and formed into a small rod shaped solid briquetting fuel. The entire production system can achieve closed transportation, negative pressure dust reduction, and clean production. Discharge size: 50-120mm, processing capacity: 10-50t/h